Clean-S Treatment Type A

Clean-S

Inquiry of this product

About the products

Features of Clean-S Type A

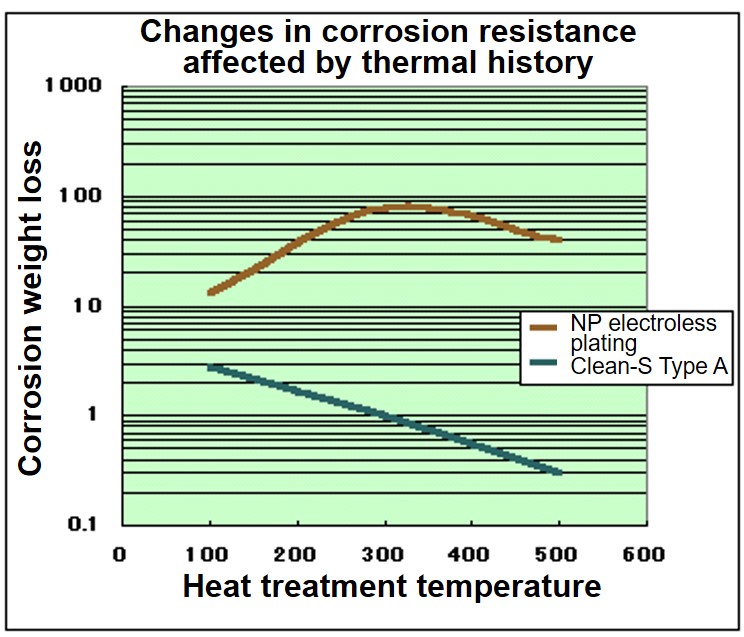

- 1 ) Resonac’s Clean-S Treatment Type A uses electroless treatment technology to deposit Ni alloy films for surface treatment, and provides excellent heat resistance due to its different alloy constituent elements and compositions.

- 2 ) Superior corrosion resistance does not deteriorate even under the influence of thermal history, unlike ordinary electroless plating.

- 3 ) High surface hardness and excellent wear resistance help enhance the galling resistance of sliding parts. Micro-Vickers hardness: Hv = 1100 (under a given heat treatment)

- 4 ) Superior corrosion and mold release properties when molding at high temperatures with polypropylene (PP), polyethylene (PE), Teflon, and other materials.

Treated test pieces are subjected to the thermal history of a given temperature for two hours in a furnace for inert gas displacement heat treatment, before being cooled. The results are compared in terms of corrosion resistance at room temperature.

Marketed NiP plating induces coating crystallization at a temperature history of 300℃ or higher, resulting in the loss of corrosion resistance (declining to 1/8 of the initial level), but Resonac’s Clean-S treated films cause no such problems.

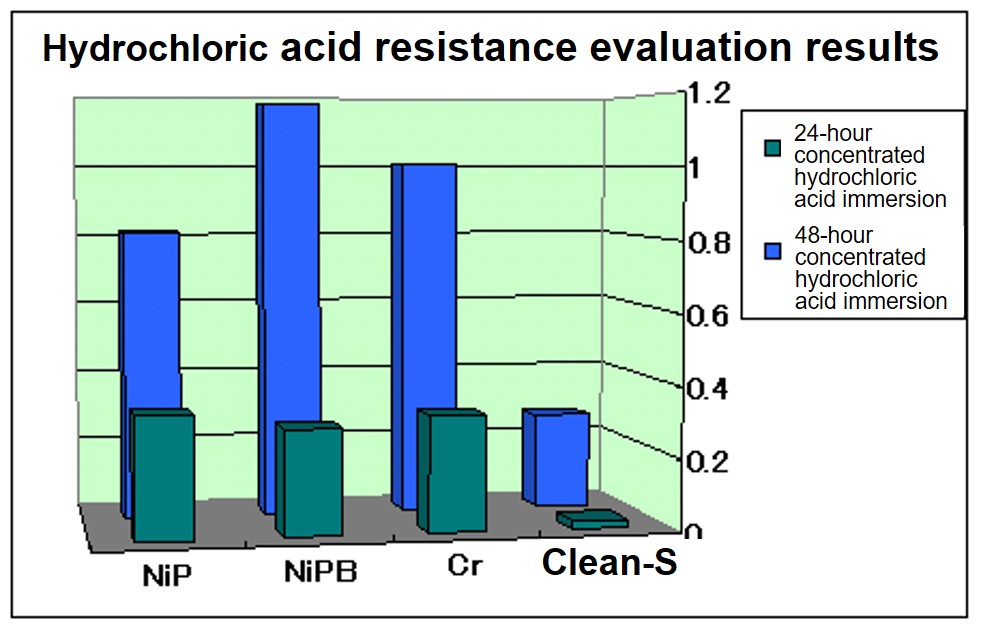

Clean-S Type A: HCl resistance properties

Shown below are the evaluation results of the hydrochloric acid resistance properties of Clean-S treated film Type A.

Test method

Exposure condition: immersion test in a 35% HCl solution

Time: measuring the weight change of test pieces after 24 and 48 hours

The relative change is indicated with Cr plating’s 48-hour weight loss defined as 1.

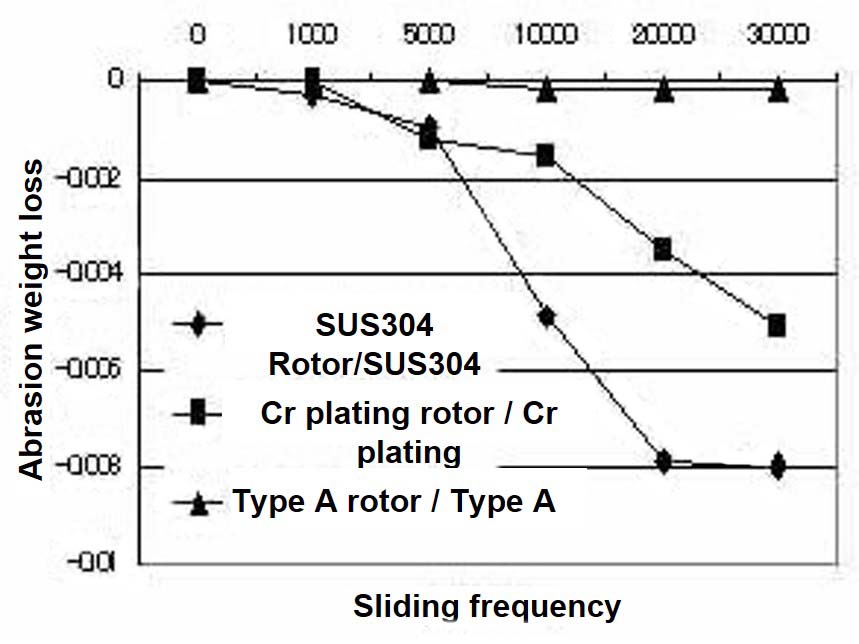

Abrasion resistance of Type A (heat-treated items)

Surface treatment is applied to flat plates and rotors made of SUS materials to evaluate the degree of abrasions and stains.

Measurement conditions

Load: 500g

Travel speed: 1.5 sec/1 round trip

Number of round trips: 30,000 times

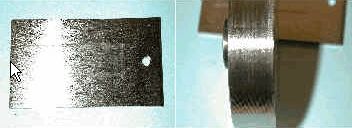

Images after abrasion tests

Base material SUS and Cr plating wear away as seen from stains and rust on their surfaces.

Flat plate: Type A / Rotor: Type A

Flat plate: SUS / Rotor: SUS

Flat plate: Cr plating / Rotor: Cr plating

Abrasion weight loss comparison

Inquiry of this product