- Category:

- Tag:

Applicable Business AreasGlass, window sash manufacturers

Target ApplicationsSealing materials for vacuum insulated glass

Applicable Business AreasGlass, window sash manufacturers

Target ApplicationsSealing materials for vacuum insulated glass

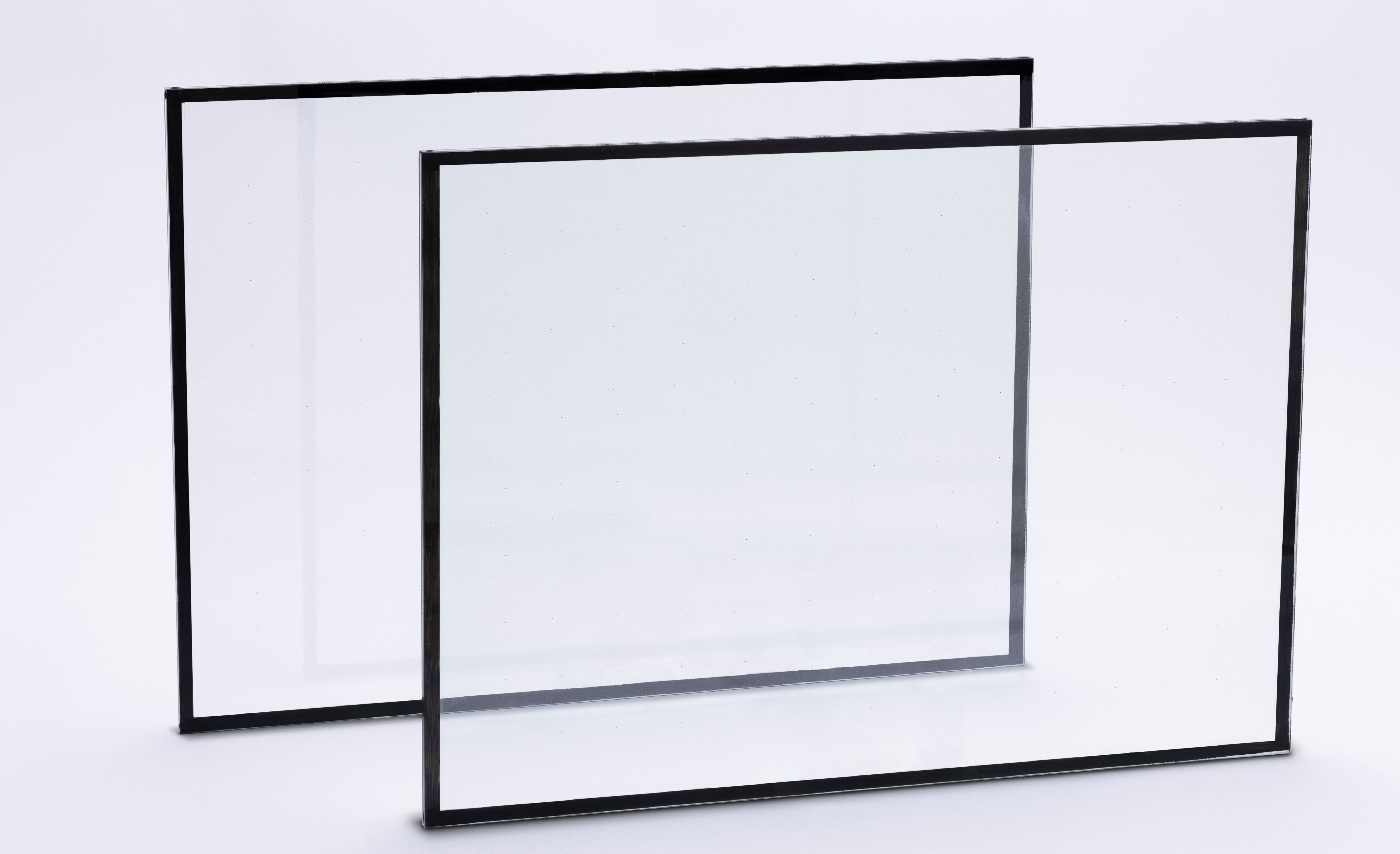

The building industry aims to improve the thermal insulation property of glass windows in the pursuit of more energy-efficient buildings. With double-glazed glass in widespread use, vacuum insulated glass (VIG) is expected to become increasingly popular to meet the demand for better insulation performance.

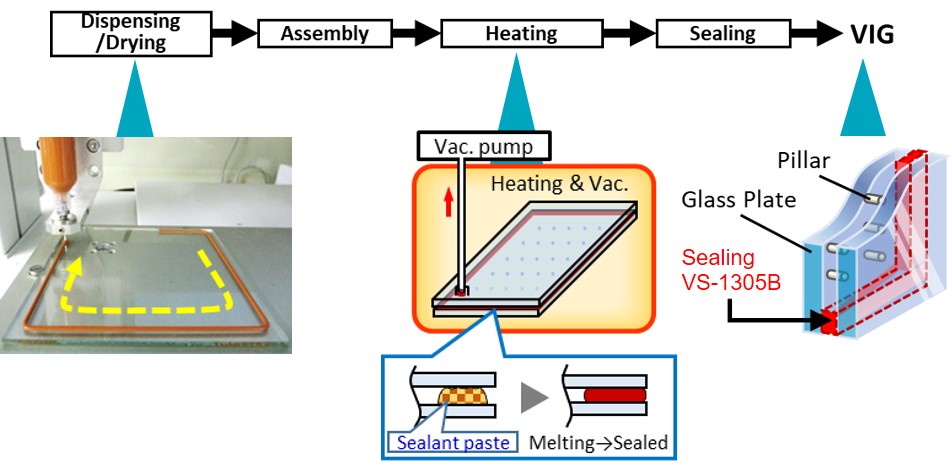

VIG uses glass instead of conventional rubber or resin, as requires sealing materials that ensure high airtightness. However, forming junctions of glass-based sealing materials involves a high-temperature heating process and poses the challenge of reducing energy consumption during VIG manufacturing. To meet this challenge, Resonac proposes its low-melting glass “Vaneetect <VS-1305B>.” This material contains silver and tellurium in its main component vanadium, and can be used for hermetic sealing applications with a low-temperature heating process.

Vaneetect VS-1305B

Vacuum Insulated Glass

VIG is manufactured by laminating sealant-coated glass with another sheet of glass, heating while degassing to melt the sealant, and forming a vacuum layer between the two glass sheets. As heating is the most energy-intensive manufacturing process, energy conservation presents a challenge for conventional VIG manufacturing involving heating at temperatures 400°C or higher.

Resonac’s low-melting glass “Vaneetect <VS-1305B>” allows VIG to be manufactured with less energy than conventional models as it forms a hermetically sealed bond with heating at 300°C.

Resonac’s material also enables the production of VIG using tempered glass. Tempered glass develops strength by accumulating stress on its surface and interior, but when heated at above 300°C, the glass releases the stress resulting in lower strength. Our material provides reliable sealing at 300°C, thereby contributing to the development of tempered VIG.

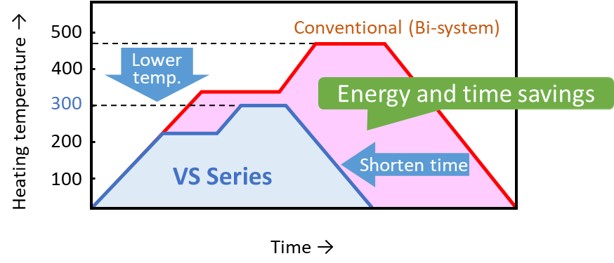

Achieving reliable bonding with conventional sealants requires heating at 400°C or higher. On the other hand, Resonac’s material provides hermetic sealing with a heating temperature at 300°C and shorter processing time.

Below is a diagram of temperature changes at sealing temperatures of 300°C and 470°C, with temperature indicated on the vertical axis and process time on the horizontal axis. The diagram shows that the heating process time can be shortened by lowering the sealing temperature, and how much energy consumption can be reduced depending on the conditions of the sealing temperatures and process time. Please contact Resonac for further details.

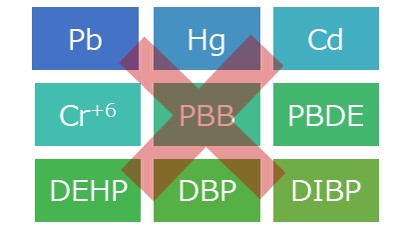

Resonac’s materials consists mainly of vanadium, blended with silver and tellurium, and is free of substances restricted by the EU’s RoHS Directive. With no lead contained, Resonac’s VIG can be recycled as glass.

Update date: 30th January, 2024

Contact Us

Please don't hesitate to contact us if you have any questions.