JAXA Adopts Resonac’s Proposal to Study Heat Storage and Utilization System for Use on the Lunar Surface

~ Creation from employees’ voluntary activities themed on cosmic materials ~

March 21, 2024

Resonac Holdings Corporation

Resonac Corporation (President: Hidehito Takahashi, hereinafter “Resonac”) proposed Japan Aerospace Exploration Agency (hereinafter “JAXA”) to conduct research into heat storage and utilization system for use on the lunar surface, which is expected to make effective use of moon sand, and the proposal was adopted by JAXA. This time, JAXA invited the public to send in entries for the Agency’s “Competition for open innovation to expand humanosphere by pioneering the frontiers of the solar system.” The proposal mentioned above was prepared by a voluntary group of Resonac’s employees, and JAXA adopted the proposal as a research program categorized as “Challenge Type” because the research topic is challenging. Resonac and JAXA will start joint research in April, 2024.

JAXA invited applications for research on “Regolith-based physical heat storage energy system” which utilizes regolith accumulated on lunar surface as heat storage material. On the surface of the moon, temperature goes down to -170 degrees Celsius. at night, and daytime and nighttime continues two weeks each with harsh temperature difference. Therefore, to carry out manned lunar surface activity, it is necessary to secure energy stably.

On the other hand, regolith consists of fine glassy particles generated by space weathering, and there is a massive amount of regolith on the surface of the moon. If we can utilize regolith as heat storage material, it will become possible for us to secure energy on the surface of the moon efficiently and at low cost. However, in order to enable regolith to store heat energy efficiently, we must increase thermal conductivity and specific heat of regolith and develop a system to extract heat from heat-storing regolith.

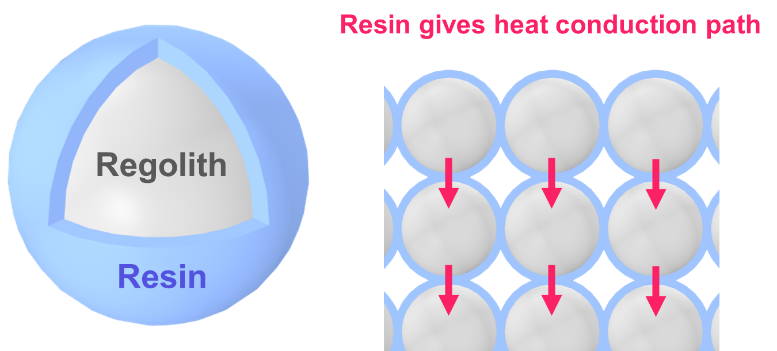

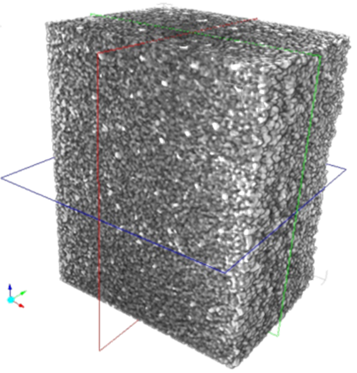

In this context, Resonac’s voluntary engineers thought it would be possible to increase thermal conductivity and specific heat of regolith by utilizing “Resin-coated Sand*1 Technology” of which the Resonac Group has a track record of mass production. With this technology, we can coat surface of regolith with resins including polyamide-imide and compact it. To confirm applicability of this technology to regolith, members of the voluntary group conducted thermal simulation of regolith by assuming the environment of lunar surface where daytime and nighttime continues two weeks each with harsh temperature difference and under vacuum in which heat is transmitted only through radiation*2. As a result of the heat simulation, the voluntary group came to a conclusion that, right on the equator of the moon, resin coating on the surface of particles of regolith is expected to increase regolith’s thermal conductivity and specific heat, and enables regolith to store 20 times as much daytime sunlight heat energy as that of regolith without resin coating. In the past, there were some studies that utilized laser heating to vitrify regolith and improve its heat storage performance. However, it was a problem that laser-heating method requires transportation of heavy laser light generator and a lot of energy to heat and vitrify regolith. The method suggested by Resonac this time enables astronauts on lunar surface to coat the surface of regolith particles with resins through screw kneading. If this method is put into practical use, astronauts can mass-produce resin-coated regolith with remarkable energy efficiency. Resonac executed the thermal simulation and verification of heat storage performance of resin-coated regolith within a short period of time because Resonac’s Research Center for Computational Science and Informatics has advanced simulation technology. JAXA acclaimed this originality of Resonac’s proposal, and adopted it as a research program categorized as “Challenge Type.”

Resonac will coordinate the plan and system for research, aiming to launch the joint research with JAXA smoothly. Then Resonac and JAXA will search for the way to realize transformation of regolith into heat storage material, develop and verify heat energy storage system for use on lunar surface with good cost performance. The period of the joint research with JAXA is expected to be 1 year at the maximum.

This time, the proposal was prepared by an in-house voluntary group. Aiming to achieve its Purpose, “Change society through the power of chemistry,” Resonac established an in-house community activities promotion program named “REBLUC (Resonac Blue Creators)” in 2022. Under this program, engineers who desire to contribute to society through the development of cosmic materials gathered voluntarily, and have been promoting this project.

*1: Resin-coated sand is used in manufacturing of cast-metal objects. When it is heated, its resin layer melts and reacts with hardening agent to make resin-coated sand into hard object. Resonac Techno Service Corporation, a member of the Resonac Group, manufactures resin-coated sand.

*2: There are three ways in transmission of heat, namely, radiation, conduction, and convection. Radiation is a phenomenon in which heat is transmitted through electromagnetic waves emitted from heated object. In a vacuum, heat is transmitted only through radiation.

For further information, contact

Public Relations Group, Brand Communication Department