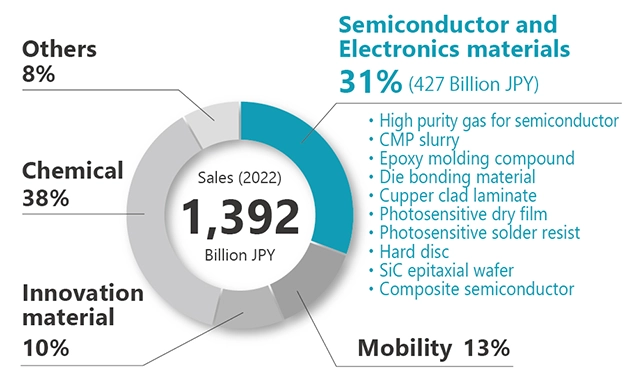

Resonac is a function chemical company that integrated Showa Denko and Showa Denko Materials (former Hitachi Chemical) in January 2023. Semiconductor and electronic materials currently account for more than 30% of Resonac Group's sales among its lineup of chemical products, and are expected to achieve the highest operating income by segment. Resonac Group is leading the way in the field of back-end materials.

Global No.1 Manufacturer of Semiconductor Back-end Materials

Sales by Segment

Sales of Semiconductor Back-end Process Materials

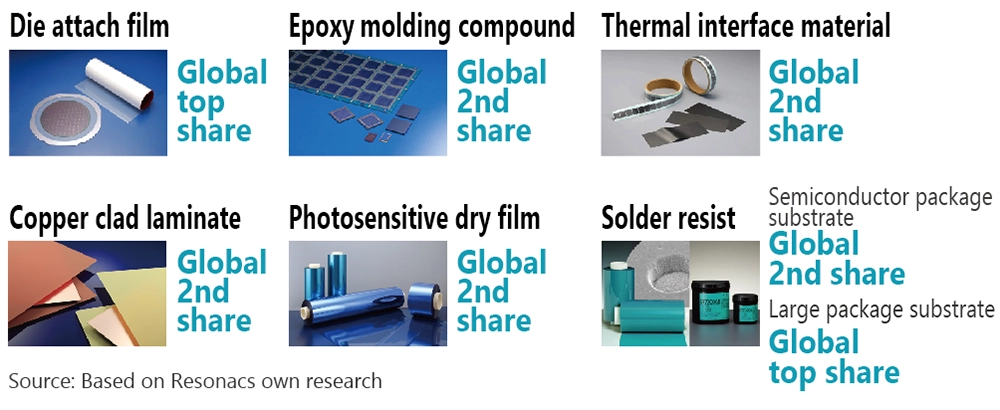

Global Top Level Market Share Products

Resonac group has global top level share materials for semiconductor.

Features / Advantages

- Die attach film

- Epoxy molding compound

- Thermal interface material

- Copper clad laminate

- Photo-sensitive dry film

- Solder resist

Die attach film

Die attach films feature a hybrid composition of epoxy, acrylic rubber resin, and nano-filler (Resonac holds a composition-of-matter patent) that allows the films to be temporarily heat-compressed on a substrate. After thermosetting, the high adhesive strength of the epoxy components and the flexibility (stress relaxation) of the rubber components contribute to maintaining the stable adhesion and electric connection of packages even under severe temperature conditions.

Epoxy molding compound

After acquiring part of Nitto Denko’s encapsulating materials business in 2012, we achieved the high-filling amount of inorganic materials and the high fluidity of encapsulants by combining Nitto Denko’s kneading technology and our compounding technology, contributing to higher formability and reliability. With foreign substance control becoming increasingly strict for automotive applications in recent years, we have developed a countermeasures line to provide high quality encapsulants.

Thermal interface material

Resonac Group’s Thermal interface material sheets feature thickness accuracy and flexibility (followability) superior to conventional materials, contributing to optimal thermal management.

Other firms’ products are horizontally oriented to dissipate heat, but Resonac Group’s products are vertically oriented, a unique feature increasing our presence in the market.

Copper clad laminate

Resonac Group’s products use unique, low CTE (coefficient of thermal expansion) resins for substrate materials to uniformly increase the filling amount of inorganic materials, thereby reducing warpage and enhancing hardness. These products also feature the diametric function of enabling easy hole drilling.

In addition, our products offer excellent connection reliability and low transmission loss, and can contribute to the function of mass simultaneous computation.

Photosensitive dry film

Resonac Group’s resin design technology is utilized to achieve excellent resolution, line-width stability, and high adhesion to substrates.

Our products also help to efficiently pattern fine-pitch circuits in laser direct imaging.

Being able to offer a lineup of thick films for various applications is an additional strength.

Solder resist

Resonac Group’s products provide low thermal expansion and low shrinkage to realize reduced warpage, facilitating the mounting of semiconductor package substrates.

Our products also offer excellent resolution, high reliability, and particularly, superior resistance to cracking.

Pioneering the Next Cutting Edge Semiconductors

With finer-pitch patterns in the front-end process reaching their limits in terms of technology and cost, companies around the world are focusing their efforts on technological innovations in the back-end process.

There is a limit to what one company can do to meet today’s rapidly accelerating pace of technological innovation. As a pioneer of the next cutting edge semiconductors, the Resonac Group has established an open innovation center to co-create with other firms with the aim of becoming a one-stop partner speedily providing highly reliable materials.

Packaging Solution Center

The Packaging Solution Center was established in 2018 in Kawasaki City, Japan, as a research and development hub for semiconductor back-end process technology. To create cutting-edge technologies for increasingly advanced, complex semiconductor packages, including memories, servers, autonomous vehicles, and other applications, the facility comprehensively assesses the back-end manufacturing process to enhance material functionality and offer greater value to our clients.

JOINT2

JOINT2 is a co-creation consortium consisting of 13 Japanese semiconductor materials, devices, and substrates manufacturers, including the Resonac Group. The consortium aims to help resolve technical issues involving the next-generation semiconductor packages required for 5G and post-5G networks by utilizing evaluation platforms to develop evaluation technologies, substrates, materials, and devices.

- * Project funded by the New Energy and Industrial Technology Development Organization (NEDO). Research and Development Project of the Enhanced Infrastructures for Post-5G Information and Communication Systems. (JPNP20017)

News Releases Related Semiconductor

- 2023.07.27 Business “JOINT2” Consortium Enhances Its Proposal Capability for the Development of Next-Generation Semiconductor Packaging Technologies

- 2023.04.04 Business Resonac Increases Production Capacity for Adhesive Film for Semiconductor Packaging by 60%

- 2023.03.31 Business DENSO Adopts Resonac’s SiC Epi-wafer for Power Semiconductor for Use in Inverter