- Category:

- Tag:

Applicable Business AreasFood industry

Target Applications Food containers

Applicable Business AreasFood industry

Target Applications Food containers

The amount of food wasted by food-related businesses and households in Japan was estimated to be 5.23 million tons per year1), so the food industry is making various efforts to overcome this problem by extending the shelf life of foods. In addition, with an aging population and a diversity of tastes, food containers need barrier-free features such as easy opening and safety as well as designability.

Conventionally, plastic food containers have been used widely for their easy opening and designability. But the momentum to cut plastic usage has been growing in recent years due to the high environmental load of plastic production and disposal. The Japanese government has set a goal of reducing plastic waste by 25% by 20302). Plastic containers’ high recycling cost is also a problem. In Japan, recycling entrustment fees in accordance with the Container and Packaging Recycling Law are no longer negligible. Efforts to reduce plastic and adoption of recyclable containers are becoming crucial in the food container industry.

Resonac proposes “ALMIC-CAN”. The “ALMIC-CAN” is a food container made from laminated aluminum foil and resin sheets, which provide long-term food preservation and easy opening as well as reduction of plastic.

“ALMIC-CAN” is a people- and environment-friendly food container that contributes to solve food-related challenges and reduce plastic usage.

Various materials are used for food containers, but each material has its own downside. For example, paper is not suitable for long-term food preservation, cans are hard to open, plastics have a high environmental load, and glass containers break easily.

Resonac’s "ALMIC-CAN" is a food container made by press-molding laminated aluminum foil and resin sheets. This container enjoys the merits of aluminum and plastic.

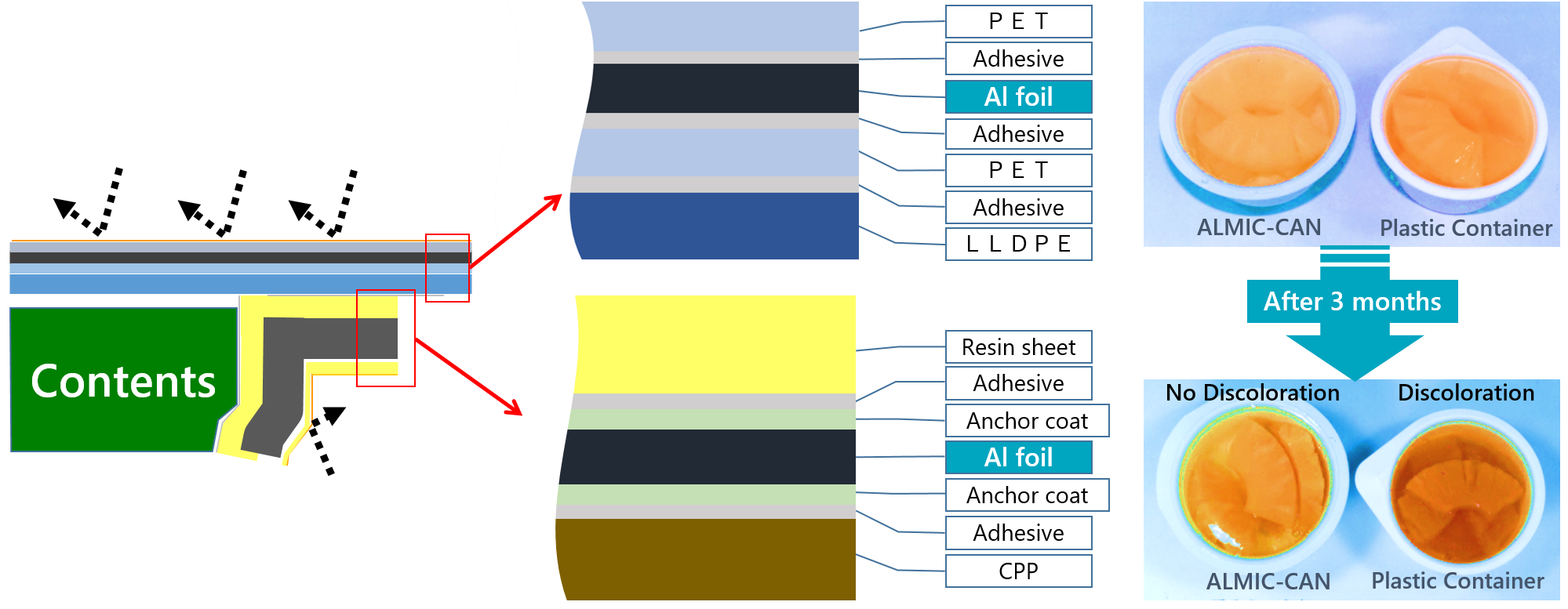

Whether used in the lid or the container, the aluminum foil layer of “ALMIC-CAN” blocks the flow of oxygen, moisture and light, enabling long-term food preservation. The double-structured resin sheet comprised of a sealing layer and a peeling layer makes the containers easy to open even for children or seniors. Similar to plastic, the material also allows design flexibility. With an aluminum content rate exceeding 50%, “ALMIC-CAN” contributes to reducing plastic and is categorized as an “aluminum can” under the Law for the Promotion of Effective Utilization of Resources in Japan. “ALMIC-CAN” has been proved recyclable as aluminum.

This container has been on the market for more than 30 years and has been used in a wide variety of applications as outlined below.

What is "ALMIC-CAN"?

The use of aluminum foil in both the lid and container prevents the ingress of oxygen, moisture, and light from the exterior, thus preventing oxidation, drying, and discoloration of the food. After the can is filled with food, it can be sterilized by heat and pressure. Because food in retort pouches can be heat-sterilized while still sealed, the loss of water-soluble nutrients or those that may be easily oxidized is minimized. The sterilization processing allows food to be distributed and stored at room temperature.

According to Resonac’s data on the results of L-ascorbic acid storage test in “ALMIC-CAN”, the reduction of L-ascorbic acid was slowed with a greater amount remaining compared with competing packaging materials, indicating that “ALMIC-CAN” inhibits oxidative degradation over time.

Please refer to the technical material for specific details.

Layer of "ALMIC-CAN" and long-term food preservation

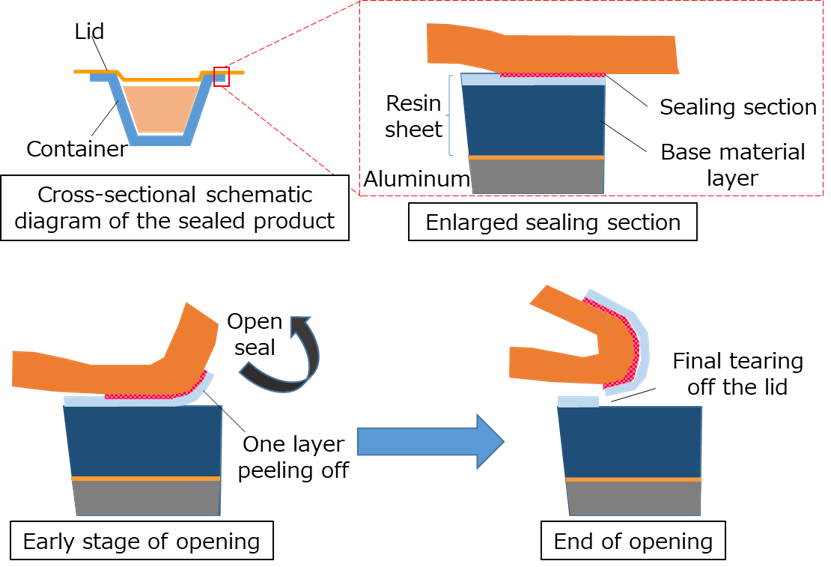

The resin sheet consists of a peeling layer and a sealing layer. The peeling layer can be easily peeled away from the base material layer, with the sealing layer being completely welded, thus making the container resistant to internal pressure, easy to open, and leak-proof. The can is designed to have a standard opening strength of 15N, which is considered to be easy for people to open, combined with a high sealing strength of 50kPa or higher. This allows children and elderly people to open the can easily.

Because CPP (cast polypropylene) is used for the outermost layer, containers can be printed to give a high-quality feel by making use of the metallic luster of the aluminum layer. It will thus be possible to produce containers with high levels of visibility and quality of design depending on your ideas.

Easy opening of "ALMIC-CAN"

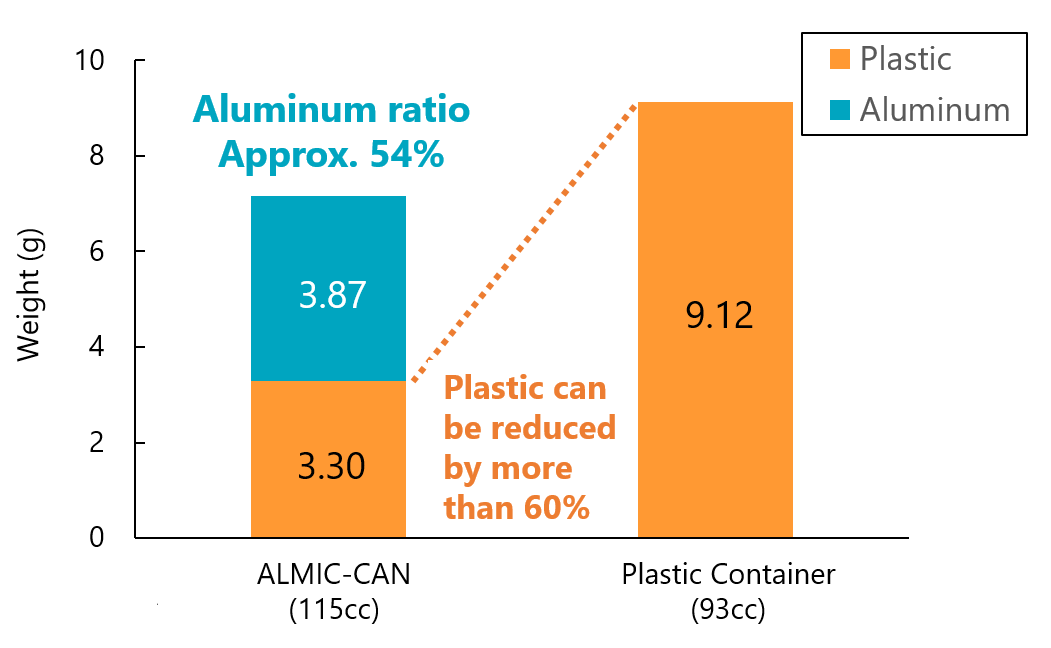

Although the effect varies depending on a container’s design, it is estimated that plastic usage is reduced by more than 60% when using “ALMIC-CAN” instead of plastic containers as shown below.

With an aluminum content rate exceeding 50% as shown in Table below, “ALMIC-CAN” is categorized as an “aluminum can” under the Law for the Promotion of Effective Utilization of Resources in Japan and is therefore authorized to use the aluminum recycle mark. By using containers marked as “aluminum” 4) instead of “plastic,”3) customers can reduce the recycling entrustment fees. Assuming one plastic container weighs 5 grams, 0.31 yen per unit can be saved5).

“ALMIC-CAN” has also been proved recyclable as aluminum. Please refer to the technical material for details.

Comparison of the amount of plastic

Components and contents of "ALMIC-CAN" (calculated value)

Contact Us

Please don't hesitate to contact us if you have any questions.